KOPLER-MISO-HRCP110-ATRYPHTO

KOPLER-MISO-HRCP110-ATRYPHTO

HRCP 110 COUPLING

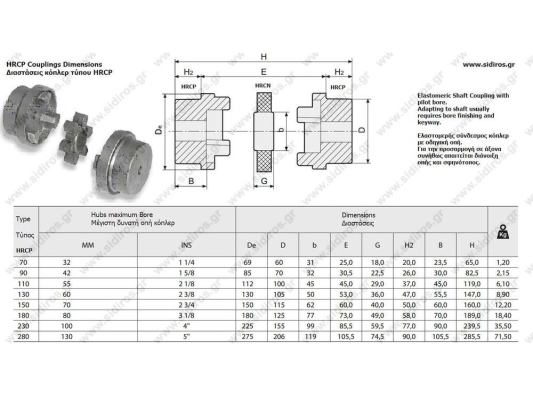

Elastomeric shaft coupling. HRCP110 couplings have a Φ110mm external diameter have a 10mm diameter pilot bore and have the possibility of receiving an up to 42mm diameter shaft with boring in the lathe. The HRCP110 is only the one half of the coupling and to complete the coupling you will require another half HRCP110. It is essential that you also have the elastic coupling (black spider) HRCN110. Alternatively to complete a shaft coupling you can use a half HRCI110 or HRCE110 with the corresponding taper bush type 1610 depending on the diameter of the second shaft you possess. Taper bush type 1610 have a standard bore diameter Φ14 Φ15 Φ16 Φ18 Φ19 Φ20 Φ22 Φ24 Φ25 Φ28 Φ30 Φ32 Φ35 Φ38 Φ40 Φ42mm with keyway. Make sure when you purchase the HRCE or HRCI coupling that you have available the right taper bush type 1610 with the desired bore diameter. HRCE coupling receives the taper bush externally while the HRCI receives it internally (from the elastic coupling side). In case the shaft you want to install the coupling to does not have any standard diameter you can use the HRCP110 coupling type which has only a pilot bore and usually requires boring in the lathe and making a keyway. HRC couplings are essentially general purpose couplings with a flexible element which can accommodate higher degree of misallignment. Parallel misallignment up to 0.5mm . Axial misallignment up to 0.7mm. Because of their superior design HRC series couplings can accomodate larger shafts shich can make them a more economical proposition. Salient features. Economy. The design of the HRC couplings has been optimised so that power capacities are balanced to the appropriate shaft diameters utilising taper lock bush fixing. Resilience. Transient peak loads are reduced by a flexible component deflexion of which is a prime design consideration. Misallignment. Incidental parallel angular and axial displacement of the connected shafts can be accomodated. Installation. quick and easy without special tools only an allen key is required. Maintenance. Virtually eliminated and no lubricant is required. Enviroment. The elastomeric component makes HRC coupling suitable for use in most conditions within a temperature range of -40 up to 100 degrees Celcius. Positive. In the unlikely event of the flexible component being destroyed the drive will be maintained by the interaction of dogs which are integral with the flanges.

HRCP110,HRCP110

HRCP110,HRCP110

SATI